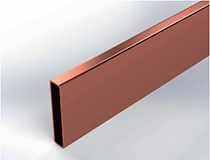

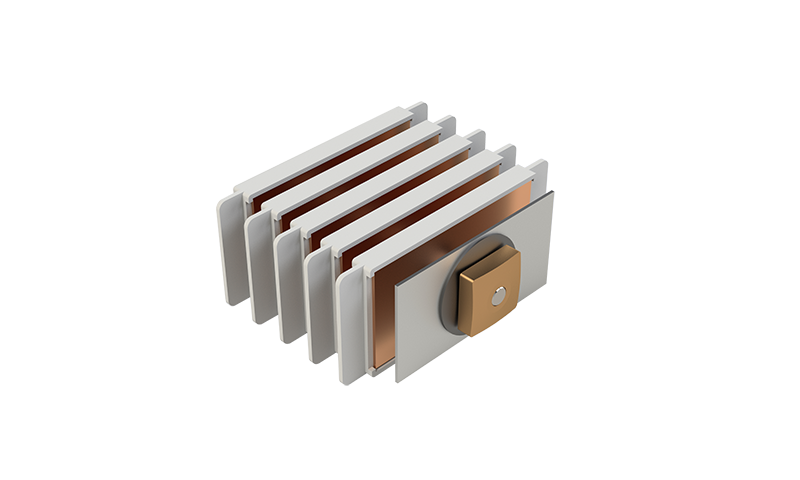

B-level insulation halogen-free insulation material

The insulation sleeve is extruded from polycarbonate material, with insulation grade B, resistant to high temperatures of 130℃, and can effectively prevent product aging under extreme environmental temperatures and extreme temperature rise. The flame retardancy grade is V0, and it does not contain halogenated compounds. The finished product has passed the 960℃ hot wire test. In the event of a fire, it will not produce harmful gases, and can effectively delay the spread of the fire to ensure the