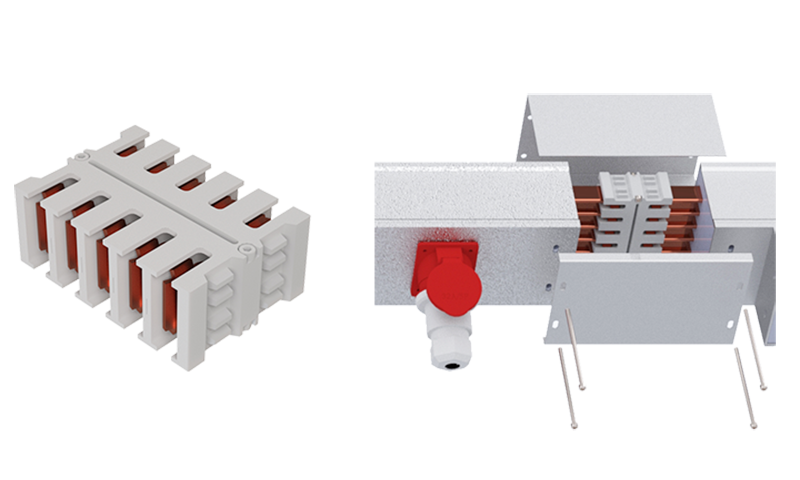

B-level insulation halogen-free insulation material

Alternative insulation separation blocks with a thickness of ≥15mm are used, with insulation grade B, resistant to high temperatures of 130℃, which can effectively prevent product aging under extreme environmental temperatures and extreme temperature rises. The flame retardancy grade is V0, it does not contain halogenated compounds, and it will not produce harmful gases in the event of a fire, and can effectively delay the spread of the fire to ensure the safe operation of the busbar.